Keramisher OFENBAU India Pvt. Ltd. is a Joint Venture Company with Keramischer OFENBAU GmbH, Germany (KOG) (www.keramischerofenbau.de), who are one of the market leaders for Tunnel Kilns and Shuttle Kilns for the Ceramic Industry.

Keramisher OFENBAU India Pvt. Ltd. is started in 2009 with a majority shareholding belonging to KOG, has realised several orders, during the last few years from their Indian branch. The company is involved in the Design, Engineering and Manufacture of Electrically Heated / Oil Fired / Gas Fired Industrial Kilns Dryers and Ovens for the Ceramic Industry. We produce and offer world class kilns to the Indian and Overseas markets. With full marketing, engineering, manufacturing and commissioning capabilities here in India, and on-line back up service and support from Germany, we are able to offer very quick and innovative solutions for your requirements – comprising of latest European technology at Indian prices with full service and spare parts support. We have worked with the top producers in India (like HSIL, CERA, Golf Ceramics, Bharat Potteries, Somany, TOTO, GLOCERA, KOHLER, etc.) and overseas ( VINAX – A Joint Venture partner of INAX- Japan, CERAMTEC- Malaysia, Asian Insulators- Thailand, Saudi Ceramics - Riyadh and Aquasan- Kuwait). We have our design and marketing offices in Noida, near Delhi and our Workshop is located in Raipur, Chattisgarh.

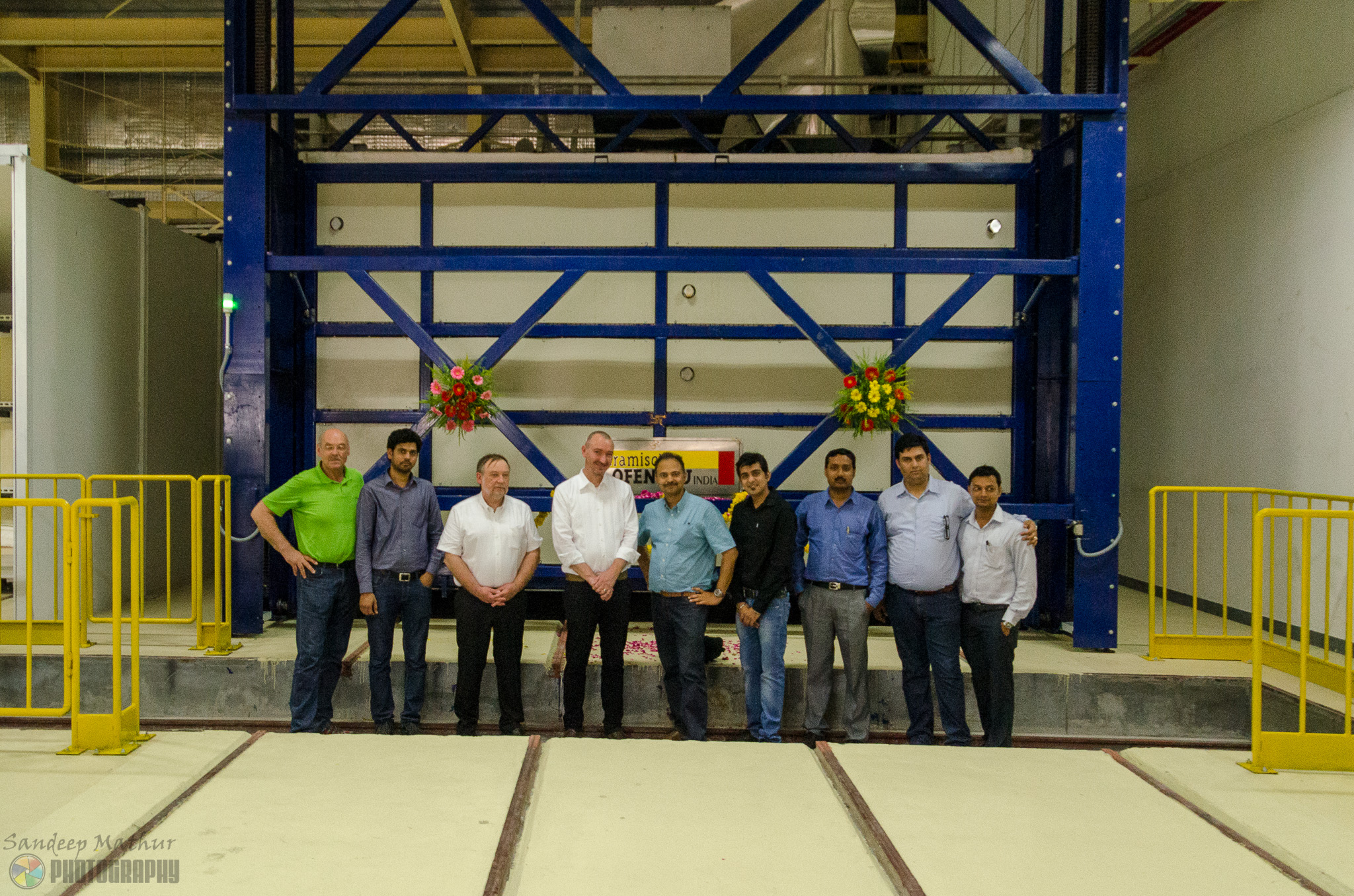

Kiln plants from Keramischer OFENBAU India.

located at Hildesheim, Germany, was formed in 1996. The team members in sales, project engineering, technical design and construction, spare parts and administration can look back on decades of experience for all fields of ceramic kiln building.